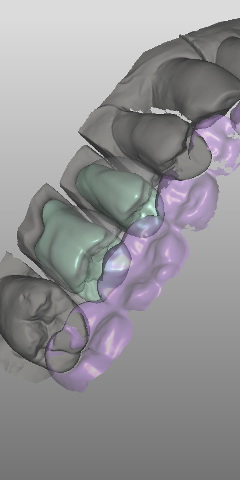

CAD - CAM Selective Laser Melting - ServicesThe alloy (Cr-Co Starbond COS Powder) that we use is free of beryllium and nickel, has a high density (8.8 g/cm3), thermal expansion coefficient is compatible with ceramic veneering masses (14.0 μm/mºC) used in dental restorationCAM - selective laser melted parts, are delivered without construction supports, so the post-processing is easy to do and less time consuming.(can be delivered also with supports if requested) For information contact usOption 1 - in case that the CAD design file is received , for CAM - selective laser melting manufacturing - the price include the manufacturing of the part with CAM - selective laser melting manufacturingOption 2 - in case that the casted impression model is received - the price include 3D scanning of casted impression model, CAD and CAM Option 3 - in case that the casted impression model is received together with wax-UP model - the price include 3D scanning of casted impression model, CAD (in conformity with WaxUp model) and CAM The first order up to 3 elements is free of charge Manufacturing time (mean values)24 hours - in case that the CAD design file is received, for singe units or bridges up to 3 elements.48 hours - in case that the CAD design file is received, for bridges over 4 elements span. +12 hours over the above cases - in case that the 3D scanning and CAD design is required. The manufacturing time will be confirmed after receiving the data (file or model) that must be processed. The above time intervals does not include the delivery time. |

For the list of services provided for dental services access the services section.

Regarding material information, access materials section.

For complete list of services that we provide and prices, please contact us.

Notes: Model Preparation and Post-Processing