|

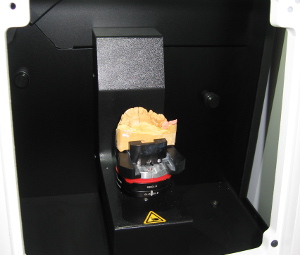

Taking the dental arch impression and obtaining the digital model (impression) After tooth preparation an impression will be taken, to obtain an exact representation of the situation from the patient mouth. This step could be accomplished by intra-oral 3D scanning (digital impression) or classic impression (negative of the dental arch) from which will be obtained a positive impression (model) of patient arch (from gypsum, resin, etc) and this model will be 3D scanned. At the end of this step the digital model must be obtained. (also the relation from maxillary and mandibular arch) We use for 3D scanning, the system Activity 855 from SmartOptics , witch has a precision of +/- 10 microns. |

|

|

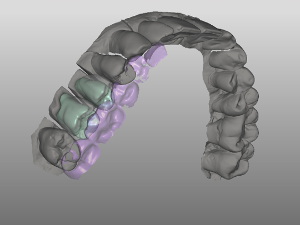

Computer Assisted Design (CAD) Using the digital dental arch impression, the dental technician design the prosthetic restoration using a dental CAD software. Using CAD software, the precision of dental prosthetics is highly improved and so the CAD software has become one of the important tools that dental technicians use. The digital file obtained after design stage will be used in the following step (computer assisted manufacturing - CAM) Taking in account the fact that the CAD software is one of the key components in the process flow, we use dentCreate CAD Software (based on exocad) from SmartOptics that enable us to design crown and coping (anatomic, reduced, offset coping, preform crowns), pontics, inlay, onlays, veneers, wax-ups, telescopes, bar structures, attachments, custom implant abutments, implant screw retained structures, etc. |

|

|

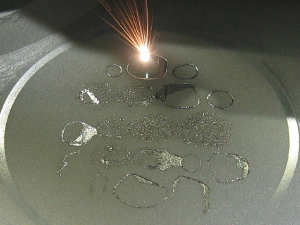

Computer Assisted Manufacturing (CAM) We used for obtaining the CoCr Alloy structure, straight from CAD file. We use Selective Laser Melting process, because is the most efficient and precise CAM process for manufacture complex and dedicated structures that fully comply with the CAD file (regardless of shape complexity). For the offer for CAD-CAM (selective laser melting) services please access Offer Selective Laser Melting. For questions and information request contact us and/or access Articles page. |

|